UPDATED 30 DECEMBER 2012

Sound really adds an extra level of realism and enjoyment to any locomotive. This article details a method used to add a Phoenix Sound P8 to a battery powered and radio controlled, Aristo-Craft GP-40.

The article may appear long because it detailed and includes lots of pictures. But if you take your time and follow it step-by-step it is not difficult, and the results are well worthwhile. Although a GP-40 was used for this installation, the instructions could be used as a guide to install a Phoenix Sound P8 in other Aristo-Craft 4-axle diesels.

OPENING THE LOCOMOTIVE

Remove the cover for the switches from the top of the locomotive.

Remove the handrails from the sides and ends of the locomotive.

Place the locomotive upside down on a soft engine cradle taking care not to damage the horns.

- Remove the ten screws outlined in yellow that hold the shell to the frame, and place them in a small container so they do not get lost.

- Two are at the very front behind the short hood pilot. Do not remove the screw in the center.

- Two are near the edge of the frame in front of the rear wheels of the front truck.

- Two are under the rear of the front truck.

- Two are just in front of the rear truck.

- Two are at the very rear behind the long hood pilot. Do not remove the screw in the center.

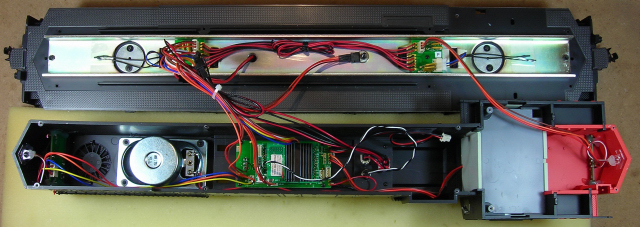

Turn the locomotive over and set it on its wheels. Lift the shell from the frame from the back to the front. The long hood, cab and short hood will all come off as one piece. Set the shell on the engine cradle beside the frame taking care not to damage the horns. If the instructions from the previous article were followed, the components and wiring should look like the following picture.

Fasten the 10 screws in the small container back in the shell.

Remove the cable tie from the wiring.

Unplug the 3 and 6-pin connectors indicated with yellow arrows from PCB04 on the rear of the frame.

Unplug the 3-pin connector for the front lights from PCB05 on the front of the frame.

Unplug the remote linking button connector from the back of the receiver.

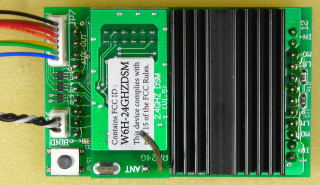

Lift the receiver from the Plug and Play socket and set it aside for now. Unplug the 3-wire connector from header labeled “REG” on the bottom edge PCB01.

Unplug the battery pack from the connector soldered to the center terminals of the battery pack switch.

Unplug the connector wired to PCB04 from the connector soldered to the outside terminals of the battery pack switch.

Set the frame aside for now.

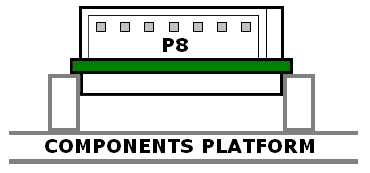

P8 SOUND BOARD PLATFORM

The P8 sound board will be fastened to a small styrene platform and mounted on the wall of the long hood behind the cab.

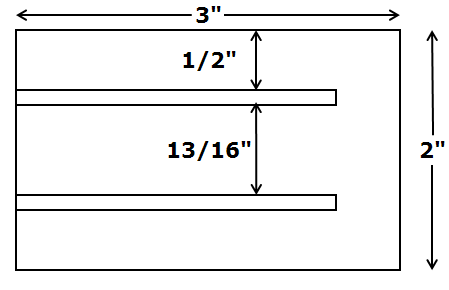

Cut a 2 x 3 inch piece of styrene from a 1/16th inch thick sheet.

The sound board will be mounted on styrene strips glued to the platform. Raising the board will allow air to cool the bottom of it. Cut two strips 2 1/2 inches long from a 1/8 x 1/4 inch strip. Cut two additional strips exactly 13/16ths inches long.

Draw a line 1/2 inch in from the edge of the platform. Use CA (super glue) to fasten one of the long pieces on edge inside the line. The strip should be flush with one end of the platform.

Using the small pieces as spacers, fasten the other long piece on edge to the frame exactly 13/16ths of an inch from the first. When the glue has dried, remove the spacers.

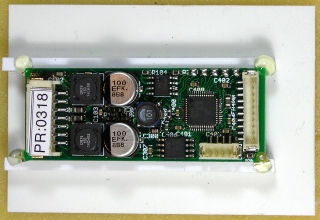

Place the sound board on top of the two styrene strips. The components on the bottom of the P8 should sit in between the strips, while the edges of the circuit board sit on top of them.

The header C1 with the serial number should be about 1/8 of an inch from the end of the strips that are flush with the end of the platform. Fasten the sound board to the strips with small dab of hot glue at each corner.

The P8 sound board has 3 headers to plug in three matching connectors: C1 with 6 wires, C2 with 9 wires and C3 with 3 wires. Plug wire connectors C1 and C2 into their matching headers on the sound board.

That completes the assembly of the sound board platform. It will be mounted on the wall of the long hood after the P8 sound board programming jack is installed.

P8 SOUND BOARD WIRE CONNECTOR C3

On the end of connector C3 is the programming jack for the Phoenix Sound Computer Interface. This accessory is used to customize sound files or upload upgraded ones. Every sound function can be modified or replaced to suit the locomotive owner’s personal preferences.

The programming jack must be installed, before connector C3 can be plugged into the sound board. Drill a 5/16ths inch hole in the locomotive’s switch panel just behind remote linking button and battery pack charging connector.

Remove the locking nut from the programming jack wires. Install the jack in the hole. As there is not enough threads to install the locking nut, fasten the bottom of the jack in place with hot glue.

Plug connector C3 into its matching header C3 on the sound board.

On the bottom of the sound board platform, place a dab of hot glue about 1/2 inch in from each corner. With connector C1 facing the up, hold it in the long hood near the flat wall behind the cab. Move the platform until it is flush with the top of the wall and against the battery switch platform. Press it into the side wall and hold it until the hot glue holds.

That completes the installation of the P8 sound board platform and programming jack.

CONNECTING THE SPEAKER

The Aristo-Craft GP-40 already has a speaker installed. On P8 connector C1 there are two brown wires (C1:3 and C1:5) with a white connector on the end. To connect the sound board to the speaker, plug the connector into the header labeled “SPK” on the front edge of the Plug and Play circuit board PCB01.

That completes the wiring of the speaker.

P8 DIESEL MOTOR SOUND

On P8 connector C1 there is an orange wire (C1:6) and a gray wire (C1:7). These wires are used to measure the voltage of the power being supplied to the motors. This allows the sound board to adjust the diesel motor sound as the locomotive accelerates and decelerates.

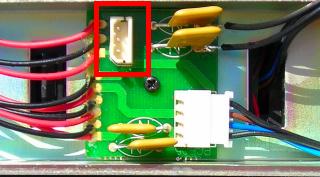

On the bottom right of the Plug and Play circuit board is a two-pin header labeled “SOUND PWR”. This header is connected to the output of the receiver used to power the motors. In order to use it however, a matching connector will be needed for the sound board’s orange and gray wires.

During the installation of the battery pack switch platform, the smoke unit was unplugged and removed. This left a connector with black and red wires soldered to the top right corner of the Plug and Play circuit board and labeled “SMOKE”. Measure up 5 inches from the circuit board, and cut the wires. There is no need to shrink wrap the wires attached to the Plug and Play board, as they will be used in the next section to power the sound board.

Plug the connector into the header labeled “SOUND PWR” near the front edge of Plug and Play circuit board. Strip a bit of insulation off all four wires; flux and tin them. Slip a length of shrink wrap over the each of the orange and gray wires. Solder and shrink wrap the orange wire C1:6 to the red connector wire, and the gray wire C1:7 to the black wire.

That completes the wiring for the diesel motor sound.

P8 SOUND BOARD POWER

On P8 connector C1 there are two green wires (C1:1 and C1:2) that are used to power the sound board. The will be connected to the red and black wires soldered to the Plug and Play circuit board and labeled “SMOKE”, which were cut to 5 inches in length in the previous section. Strip a bit of insulation off all four wires, flux and tin them. Slip a length of shrink wrap over the each of the green wires. Solder and shrink wrap green wire C1:1 to the red wire and green wire C1:2 to the black wire.

The red and black wires are connected through the circuit board to the battery power input of the receiver. They will provide constant power to the sound board even when the locomotive is stopped.

That completes the installation of the power wires for the P8 sound board.

TRIGGER WIRE INTERFACE BOARD

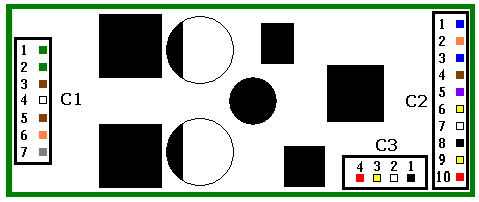

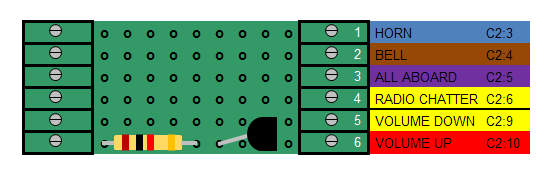

On P8 connector C2 there are 9 wires.

Three of these wires (C2:8, C2:9, and C2:10) come with a momentary switch attached to raise and lower the sound volume. But hiding the switch so it does not alter the appearance the locomotive, does not allow it to be accessed while operating. Fortunately Phoenix Sound has posted a diagram of a small circuit that can replace the switch and allow the volume to be raised and lowered with two trigger keys on the Revolution throttle. The circuit uses a resistor and a transistor which can be mounted on a small circuit between the sound board and receiver.

The circuit board also has enough screw terminals to connect all 12 trigger wires between the receiver and the sound board without soldering and shrink wrapping each pair together.

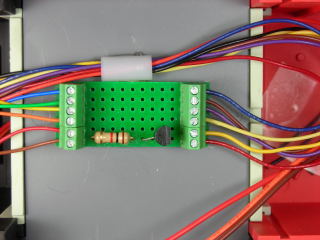

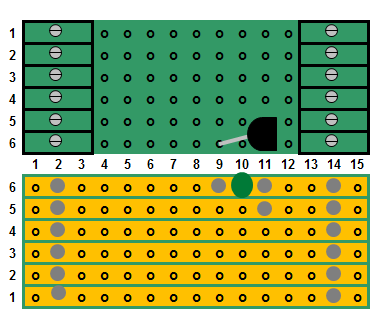

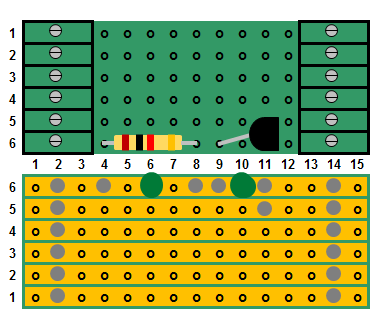

The trigger wire interface board is made from a straight trace perf board available from All Electronics under catalog number ECS-4.

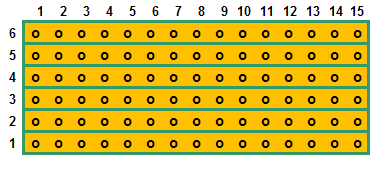

Score both sides of the perf board and snap off a piece 6 traces down by 15 columns across. Sand the edges smooth.

Fasten two, 6-position, screw terminal blocks, or any combination of terminal blocks that will cover all 6 traces, to each end of the component (green) side of the perf board with super glue. The pins of the blocks should be in columns 2 and 14, and the openings for the wires should face out.

The terminal blocks are manufactured by Phoenix Contact and are available from Mouser Electronics under the manufacturer’s part number 1725698 for the 6-position version.

Flip the perf board over. A good soldering iron of at least 40 watts and thin solder wire will be required. The pins of the terminal blocks and traces must be properly fluxed and heated before the solder is added and allowed to flow. Solder the pins of the terminal blocks to the board.

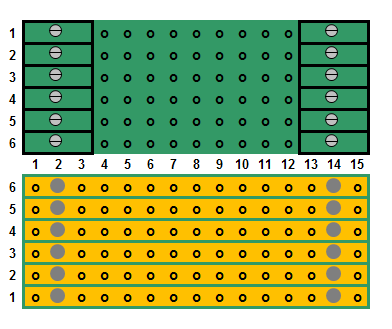

The volume control circuit uses a 1K resistor and a 2N3906 transistor which can be purchased from All Electronics under catalog numbers 293-1K and 2N3906.

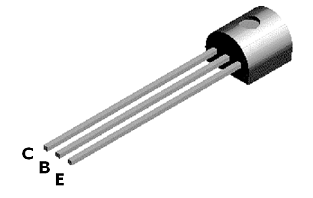

The 2N3906 transistor has three leads. If you place the transistor flat side down with the leads to the bottom, the leads from left to right are the collector, base and emitter. That’s all you have to know about this device.

Remove 1/2 an inch of insulation from a piece of yellow 22 gauge wire. Cut a piece of insulation to exactly 3/16ths of an inch. Slip the cut piece over the left lead (collector) and push it flush against the bottom of the transistor.

Remove 1/2 an inch of insulation from a piece of red 22 gauge wire. Cut a piece of insulation to exactly 3/16ths of an inch. Slip the cut piece over the right lead (emitter) and push it flush against the bottom of the transistor.

These leggings will set the transistor at the right height above the perf board for soldering and ensure they do not touch the center lead (base) when it is bent to fit. They are also colour matched to the sound board’s volume control wires C2:9 and C2:10.

Bend the center (base) lead out 45 degrees from the round side of the transistor. With the flat side of the transistor facing the right hand terminal block, trial fit the two outside leads (collector and emitter) in column 11 on the component side of the perf board. The yellow lead (collector) should be in trace 5 and the red (emitter) in trace 6. Bend the bottom of the center (base) lead until it fits in column 9 of trace 6 to the left of the transistor as shown in the following diagram. Fasten the bottom of the leggings to the perf board with a bit of super glue to hold the transistor in place.

Flip the perf board over. Flux and solder the three leads of the transistor to the perf board, and trim them. Break open trace 6 between the emitter and base leads as indicated with the big green dot, using a 1/8 inch drill bit in a pin vise.

Bend the leads of a 1K ohm resistor so they will fit in the holes of columns 4 and 8 on the component side of the perf board. Insert it in trace 6 of the board as shown.

Flip the perf board over. Flux and solder it in place, and trim the leads. Break open trace 6 between the leads as indicated with the big green dot, using a 1/8 inch drill bit in a pin vise.

Clean the perf board with flux remover. A small hobby awl run between the soldered traces will remove excess flux and solder.

The trigger interface board will be mounted in the center of the cab floor so the screw terminals are easy to reach.

Move the board back and forth across the bottom of the cab floor scoring it slightly with the bottom of the terminal block pins. Lift the board and place a good run of hot glue across the score marks on the cab floor. Carefully align the board in the center cab floor with the transistor facing the nose of the locomotive. Press the board into the hot glue.

That completes the assembly and installation of the trigger interface board with the sound volume control circuit.

REVOLUTION RECEIVER TRIGGER WIRES

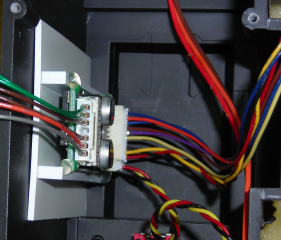

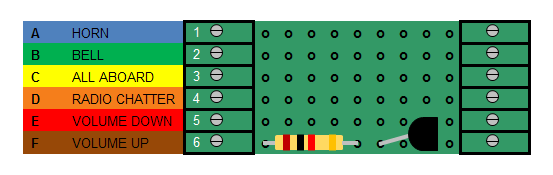

The Revolution receiver comes with a connector with seven wires of assorted colours. Plug the connector into the header on the back of the receiver labeled from “A” to “COM”.

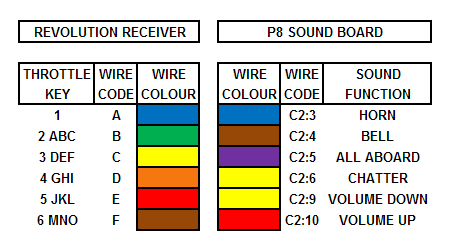

Six of these wires will be used to trigger the horn, bell, “all aboard” call, radio chatter, as well as, lower and raise the sound volume. To do this, they must be connected to the corresponding wires of the P8 sound board wire connector C2. Unfortunately the wire colours do not match, so a chart like this one is needed to connect the wires properly.

Although the wire colours do not match, in this chart the wire codes for the sound board and receiver are in ascending order, as are the throttle key designations.

The wire connector has 6 trigger wires and a black ground wire. The black wire ground will not be used in this installation. Strip 3/16ths of an inch of insulation off the ends of the 6 trigger wires, and tin them.

Turn all the screws on the terminals of the trigger interface board counterclockwise to open the wiring slots.

- On the left hand side of the trigger interface board fasten:

- the blue wire A for the horn in screw terminal 1,

- the green wire B for the bell in screw terminal 2,

- the yellow wire C for the “all aboard” call in screw terminal 3,

- the orange wire D for radio chatter in screw terminal 4,

- the red wire E to lower the sound volume in screw terminal 5, and

- the brown wire F to raise the sound volume in screw terminal 6.

That completes the installation of the Revolution receiver trigger wires.

P8 SOUND BOARD WIRE CONNECTOR C2

The P8 sound board wire connector C2 has 9 wires, but only 6 are used in this installation as that is the maximum number of sound functions the Revolution receiver can trigger at this time. Cut the momentary switch off the ends of the black, yellow, and red wires (C2:8, C2:9, and C2:10), and set it aside. Cut the bare wire tips off the blue and orange wires (C2:1 and C2:2). Tape or hot glue the blue, orange, and black wires (C2:2, C2:2, and C2:8) out of the way.

Remove 3/16ths of an inch of insulation of the yellow and red wires (C2:9, and C2:10), and tin them

Two of the wires (C2:6 and C2:9) are yellow, and must be installed under the proper screw terminals.

- On the right hand side of the trigger interface board fasten:

- the blue wire (C2:3) for the horn in screw terminal 1,

- the brown wire (C2:4) for the bell in screw terminal 2,

- the purple wire (C2:5) for the “all aboard” call in screw terminal 3,

- the yellow wire (C2:6) for the radio chatter in screw terminal 4,

- the yellow wire (C2:9) to lower the sound volume in screw terminal 5, and

- the red wire (C2:10) to raise the sound volume in screw terminal 6.

That completes the installation of all the wires in the trigger wire interface board.

TESTING THE P8 SOUND BOARD

Place the frame next to the shell. Plug the 3 and 6-pin connectors indicated with yellow arrows into PCB04 on the rear of the frame.

Plug the 3-pin connector for the front lights into PCB05 on the front of the frame.

Plug the 3-wire connector for the voltage regulator into the header labeled “REG” on the bottom edge PCB01.

Plug the remote linking button wire connector into the header on the back of the receiver labeled “BIND”. Plug the receiver into the Plug and Play socket ensuring the pins line up front and back. Tape or hot glue the black ground wire “COM” out of the way.

Plug the battery pack into the connector wired to the center terminals of the battery pack switch.

Plug the connector wired to PCB04 into the connector soldered to the outside terminals of the battery pack switch.

Gather the wires between the shell and the frame with a couple of small cable ties.

Remove the 10 screws from the shell and place them in a small container.

Place the shell on the frame ensuring that none of the wires get pinched. Place the locomotive on a set of rollers, test stand or track so the wheels can turn freely.

Turn the Revolution throttle on and select the locomotive. In the Auxiliary Function Setup menu check to ensure that Function 2 for the bell is set to “latched”.

Ensure the smoke switch is set to on, as it now provides power to the sound board. A “SOUND” label can be added later.

Be aware that throttle key 5 jkL will lower the sound volume. Toggle the battery pack switch to the run position.

Test the locomotive and sound board to ensure they respond properly to the throttle.

- From a stop, the horn should automatically toot twice in forward, and three times in reverse.

- Throttle key 1 triggers the horn,

- Throttle key 2 turns the bell on and off,

- Throttle key 3 triggers the “all aboard” call,

- Throttle key 4 triggers radio chatter,

- Throttle key 5 lowers the sound volume, and

- Throttle key 6 raises the sound volume.

After testing, return the battery switch to its center off position.

RE-ASSEMBLING THE LOCOMOTIVE

Carefully place the locomotive upside down in a soft cradle taking care not to damage the horns.

- Use the 10 ten screws in the small container to fasten the frame to the shell.

- Two go in at the very front behind the short hood pilot.

- Two go in near the edge of the frame in front of the rear wheels of the front truck.

- Two go in under the rear of the front truck.

- Two go in just in front of the rear truck.

- Two go in are at the very rear behind the long hood pilot.

Turn the locomotive over and set it on its wheels.

Fasten the handrails on the sides and ends of the locomotive.

Place the cover for the switches on the top of the hood.

CONGRATULATIONS! You have successfully added a Phoenix Sound P8 to a Aristo-Craft GP-40 with on-board, battery power and radio control.

ENJOY!