The Ironwood, Peter’s Pond and Western Railway is more than 20 years old. The railway has been designed to endure the climate extremes of the Ottawa area which range from -40 C (-40 F) to 35 C (100 F). The railway is covered with snow and ice from December to March, endures frost heaves and rains during the spring, heat and thunderstorms in the summer, and more rain in the fall.

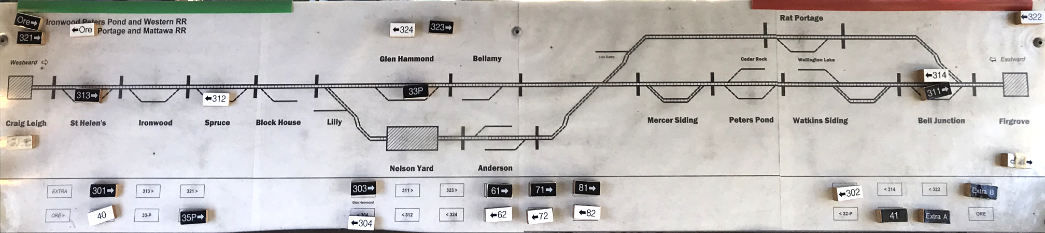

On most Saturdays mornings during the spring, summer and fall, the railway is a busy place. It is not uncommon for club members to be operating eight or more trains at a time. Despite the severe climate and heavy use, the IPP&W Railway track work has proven to be very reliable and trouble free.

Most of the mainline track is lightly nailed to 2 inch thick, pressure treated lumber. Sections are fastened together with decks screws using a 2 foot length of the same lumber. The result is a very sturdy and smooth road bed that endures frost heaves and heavy rains without failing. Sections that are flat on the ground are laid in gravel for drainage. Raised switch throws (choke cables) are set on T-bars to eliminate stooping.

Corners are cut in sections to match the diameter of the track used. The ends of all cut pieces are treated with a wood preservative to minimize water damage. Wherever possible the areas are landscaped later to hide the roadbed.

This is the same location (Lily) with an interlocked stone wall added. The temporary step was later removed. The raised areas of Ironwood and Spruce also have stone retaining walls which are both attractive and comfortable resting places for tired crew members.

The railway also features a number of large switching yards. Where possible, these yards are raised decks that provide a sturdy and flat operating area. Most of the yards have been deliberately built at a comfortable height for adding or removing motive power and rolling stock, or switching during our weekly railway operating sessions.

Originally the switching yard decks were covered with fiberglass screen and then ballasted with fine stone to the height of the ties. Fascia boards around the perimeter of the yards held the stone in place. Although this was aesthetically pleasing, it was labour intensive and added to the construction time and costs. Over time the ballast also fouled switch points, made removing dead evergreen needles difficult, grew weeds, and held moisture that promoted the premature rotting of the deck structure.

The decks are now being re-built without the screening and ballast. They are being stained a warm brown colour to make them more aesthetic and weather resistant. This may not be pleasing to those that like running trains through well maintained gardens, but our group prefers these trouble free platforms for our busy weekly railway operations.

The deck boards are fastened to 2 x 6 pressure treated cross joists with galvanized deck screws. Legs of 4 x 4 inch pressure treated lumber are fastened to the joists and mounted in concrete deck blocks set on leveled patio stones. Fascia boards are fastened to the end of the joists to give the deck a finished appearance. On the higher decks, braces are fastened across the bottom of each set of legs.

The crown of the deck boards is always fastened face up so they do not cup, hold moisture, and warp or twist. Whenever possible, the boards are spaced as shown above so that the track will run down the center of them and remain level from side to side. A belt sander can be used to remove any irregularities that would interfere with the level of any track or switches running diagonally across the boards. After the track is laid, styrene or Popsicle stick shims could be used to level any problem switches or track.

Special care is taken when installing trestles and bridges. Two inch thick pressure treated lumber is used as a base for trestles, abutments, and bridge piers. The base for these structures was later covered with river rock to create the impression of a dry river bed.

The upper roadbed for the bridges is also 2 inch thick pressure treated lumber hidden from view by wide ties, walkways, and the bridges plates and trusses. The upper roadbed is deliberately run well beyond the trestles or bridges to provide a smooth transition when entering or exiting.

These inexpensive girder bridges were built in minutes from pine boards with the ends rounded with a belt sander. They were fastened to the road bed with deck screws and later painted and lettered. The only maintenance required is the occasional coat of paint and new vinyl lettering.

While building a railway of this size may appear a daunting task, remember the IPP&W Railway is over 20 years old with additions and changes made to the track work each spring by a team of club members. The purpose of this article and others in this section is it to provide suggestions on how to build roadbed that will provide reliable track work that will last for years.