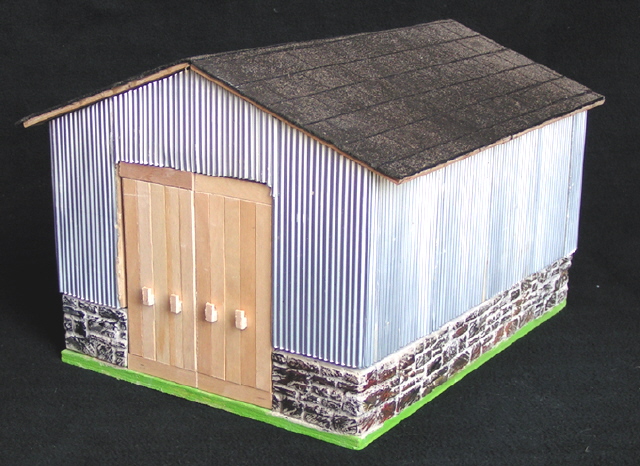

STORAGE SHED

Lawrence Watkins presented me (Doug Matheson) with a small 10 by 18 inch storage shed that he had built in 1:20 scale. This shed features the use of recycled beverage cans crimped neatly to make pieces of corrugated metal. It also has a JigStone foundation. It needs only some staining or painting of the doors and eaves and a bit of sealing plus a coat of Pentox on the plywood base to complete a nice little storage shed for the lubricants and dynamite at the quarry company office.

I liked the look of the shingles and asked Lawrence how they were done. He told me he used rolled shingle in a brown colour setting each side and then capping the center. The lines were scribed to about halfway with a fine awl. This technique has been used successfully on a few buildings but the lines may close if the building receives intense summer heat enough to soften the shingle. That will not be a problem for me with our cooler summers and my shady location.

SMALL STATION

A partial plywood frame for this station was constructed after it was discovered that a frame would help keeps the brick walls straighter.

The pieces that form the brick walls were cast with anchor cement using JigStone latex molds. Exterior grade Liquid Nails was used to glue the pieces of the walls together. When the glue dried, the stones were grouted with a grout used for floor tiles.

The brick was then dry brushed with artist’s acrylics. When the paint dried, the walls were sealed with two coats of a concrete sealer.

The arched windows and doors are resin castings, again made from molds available from our JigStones suplier. At this stage a removable plywood roof has been added.

All the windows are now installed and the freight shed doors have been added.

After the railway photographer refused to take any more building photos or update the construction logs until the rooves were finished, the roof on the small station was finally finished.

The shingles are a plastic veneer glued to the painted plywood sub-roof. A couple of coats of Krylon flat black protect the veneer from UV deterioration. Gingerbread (JigStones resin castings) were added to the roof peaks and painted dark green.

Discussions continue on how to fill the void in the peak at the front of the station. Suggestions made include a clock, sign and signaling device. Let us hope the finishing touch doesn’t take as long as the roof.

HOUSE

A heavy plywood frame for this home was constructed, and openings for the windows and doors cut out. The frame keeps the brick walls square and straight.

The pieces that form the brick walls were cast with anchor cement using JigStone latex molds. Exterior grade Liquid Nails was used to glue the pieces of the walls together. When the glue dried, the stones were grouted with a grout used for floor tiles.

The brick was then dry brushed with artist’s acrylics. When the paint dried, the walls were sealed with two coats of a concrete sealer.

The window frames are resin castings made in latex molds available from our JigStones supplier. After being painted, the frames were fastened to Plexiglas with super glue. The finished windows were then fastened in place with silicon.